IH Reflow

Damageless Mounting Technology onto Low Heat Resistance Materials

With conventional mounting techniques such as solder reflow and ACF, heat resistance is highly required for substrates and devices. For this purpose, it is inevitable to use heat-resistant substrates such as glass with low flexibility and stretchability and expensive polyimide. Our core technology "IH Reflow" is a mounting technology that applies IH (Induction Heating), and enables only parts that need to be mounted instantaneously, without physical stress (non-contact), and without damage. This technology makes it possible to mount electronic components that are not heat-resistant, even on low-heat-resistant substrates such as PET, paper, and cloth that are inexpensive and flexible and stretchable. In addition, the application of this technology can dramatically increase production throughput as an alternative to mounting processes on high heat dissipation boards using conventional lasers and hand soldering.

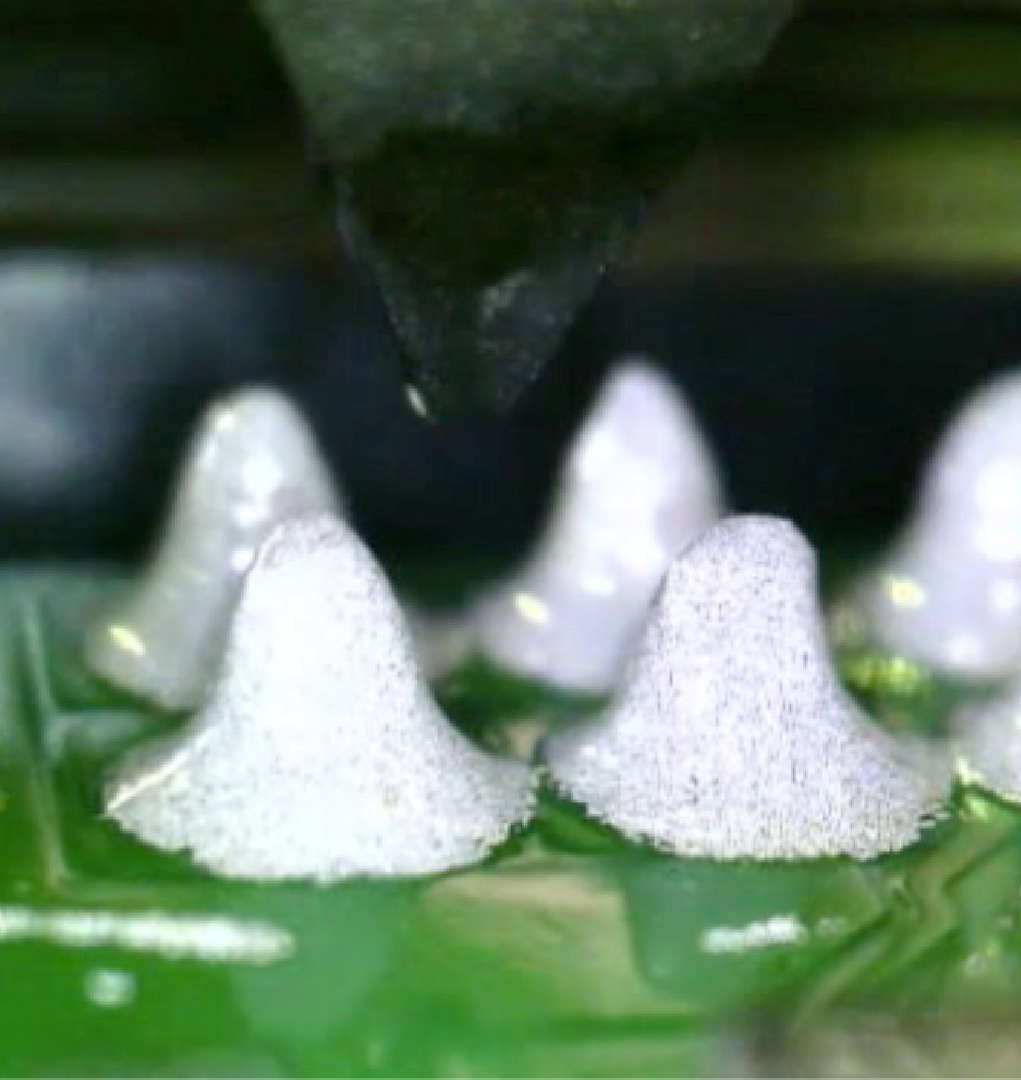

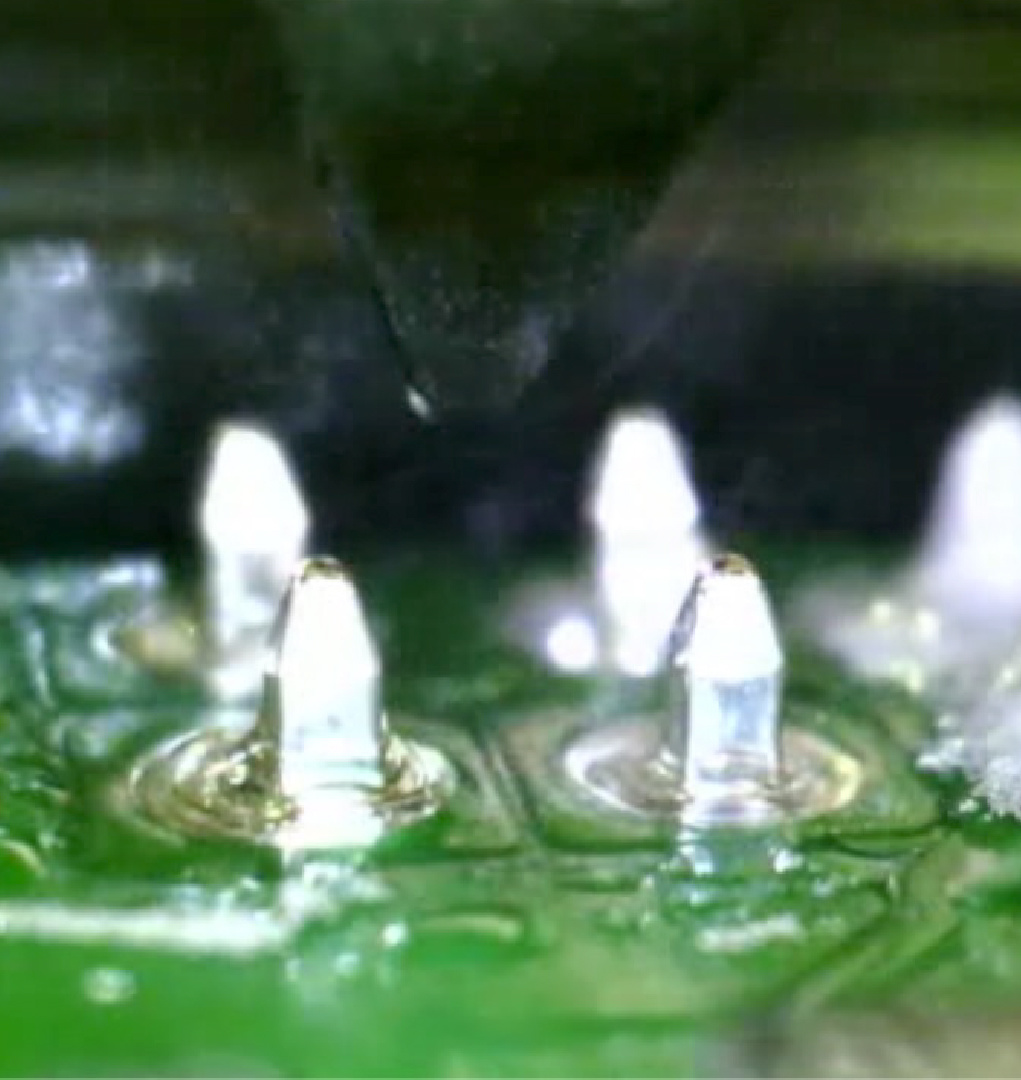

IH Spot Reflow

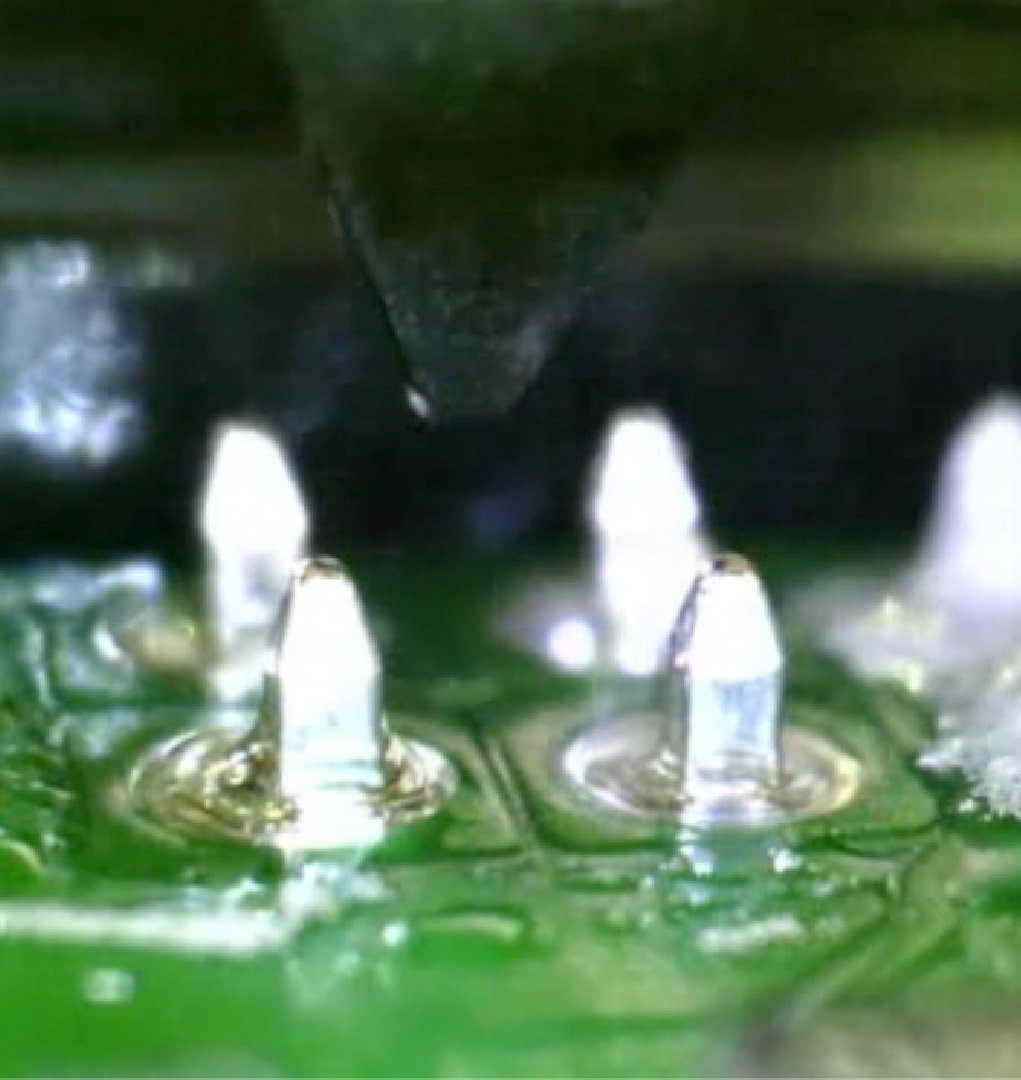

IH (Induction Heating) technology makes it possible to mount parts that require component mounting instantly and without applying physical stress to the substrate.

Similar to the principle of IH Kitchen, the base material is not heated by the magnetic field and induced current generated in the coil, but the metal wiring itself on the base material is instantly heated to melt the solder and Implement.

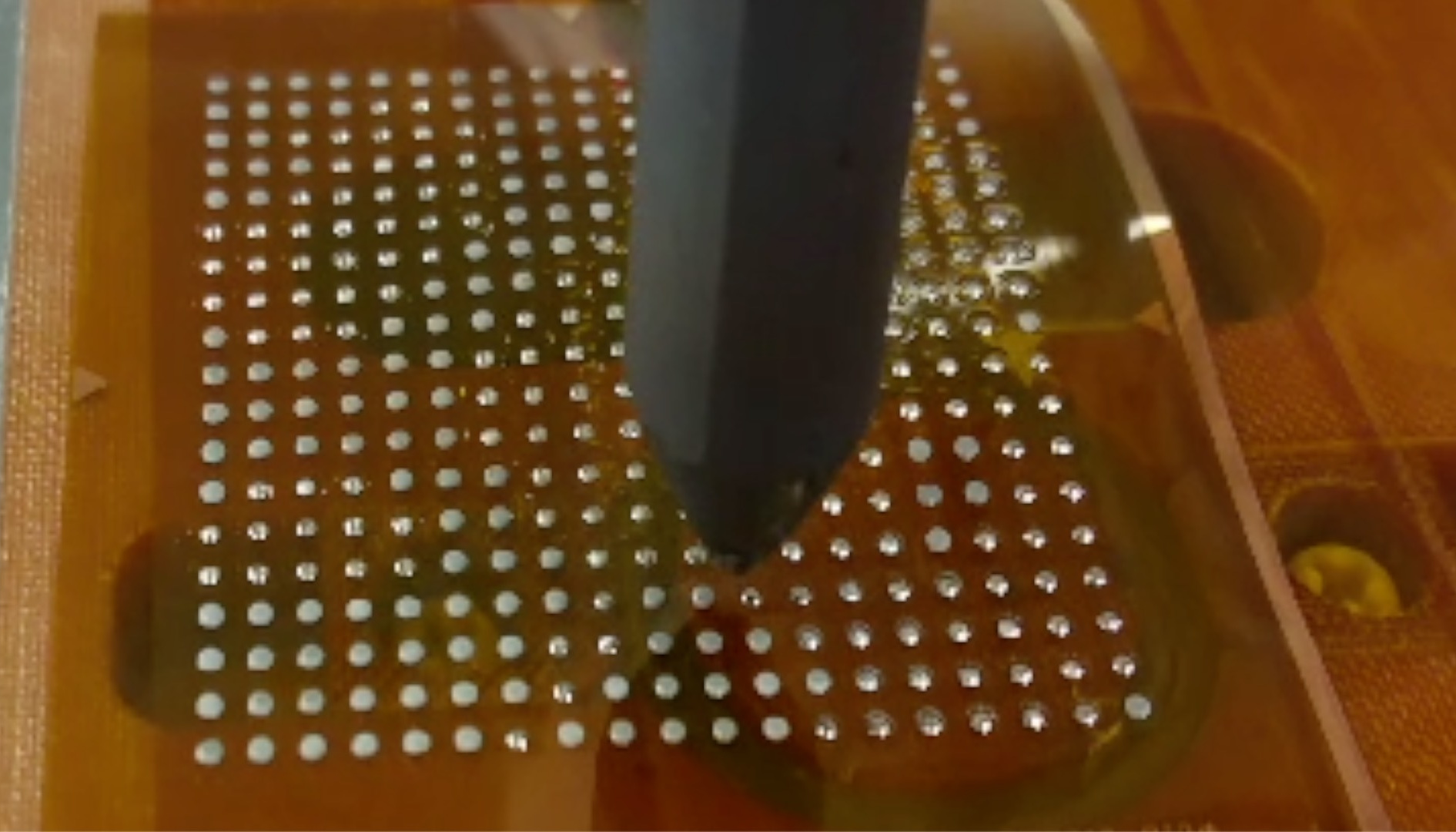

The custom nozzle for component mounting allows spot reflow as well as mounting of multiple components.

It can also be used for component mounting on low heat-resistant substrates and spot rework of specific parts.

Flexible LED Module

A flexible mini LED module in which LEDs are mounted at a fine pitch on a low heat-resistant substrate such as PET, paper, and cloth.

By placing the LEDs on a transparent PET film, it can be applied to show windows that require daylighting and the outer walls of buildings with many glass windows. Digital signage can be easily realized in stores, commercial facilities, and transportation by simply pasting directly on existing glass windows.

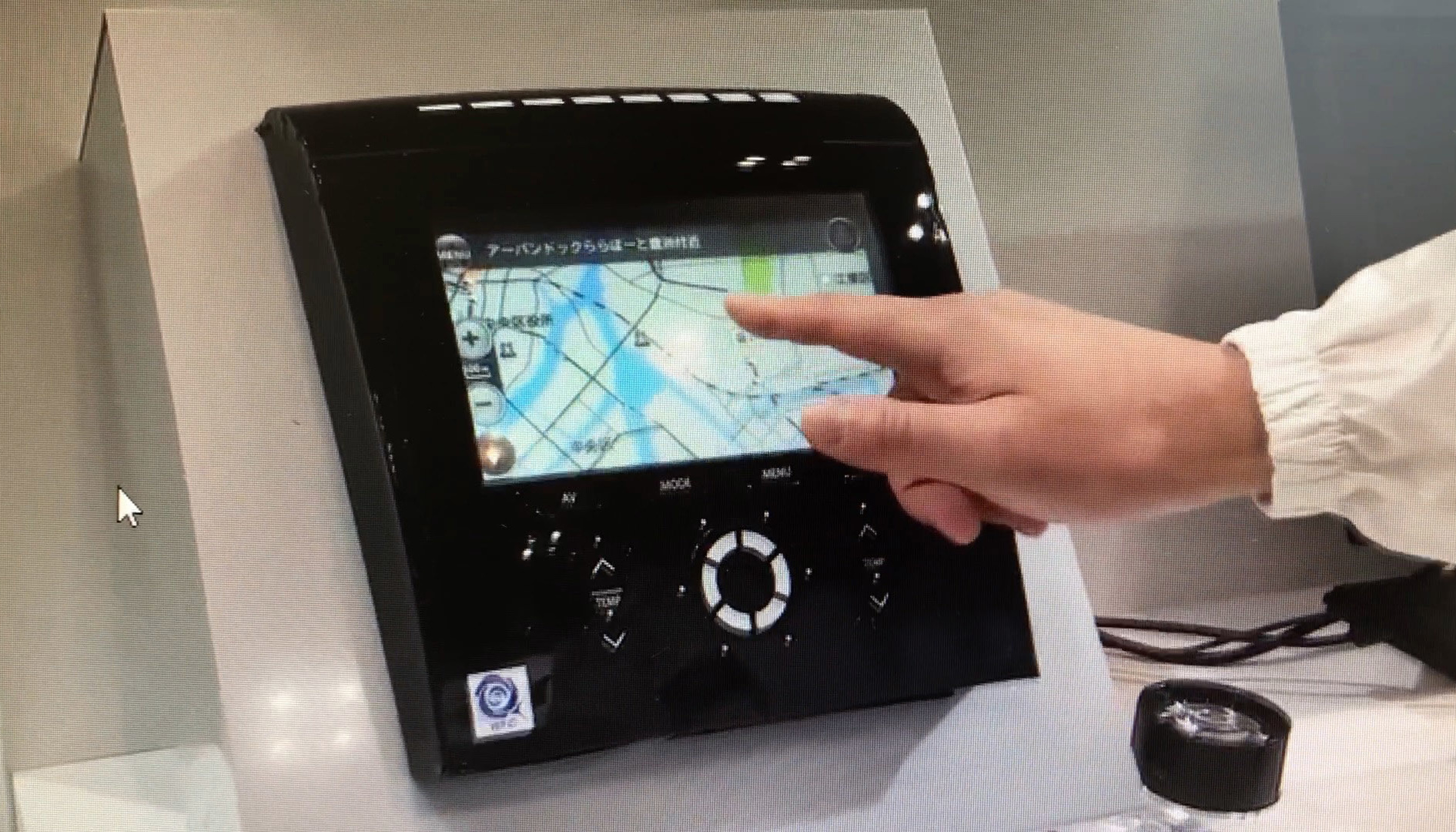

3D Touch Panel

The world's first plastic touch panel with a 3D curved surface (Patented).

Instead of the conventional flat (two-dimensional) shape, the touch panel can be bent three-dimensionally with two axes, and it is lightweight and difficult to break. In addition, the touch panel has higher added value when combined with "IH Reflow" technology that enables FPCB bonding and component mounting on low heat-resistant substrates such as resin.